YF-22

YF-22

Couldn't load pickup availability

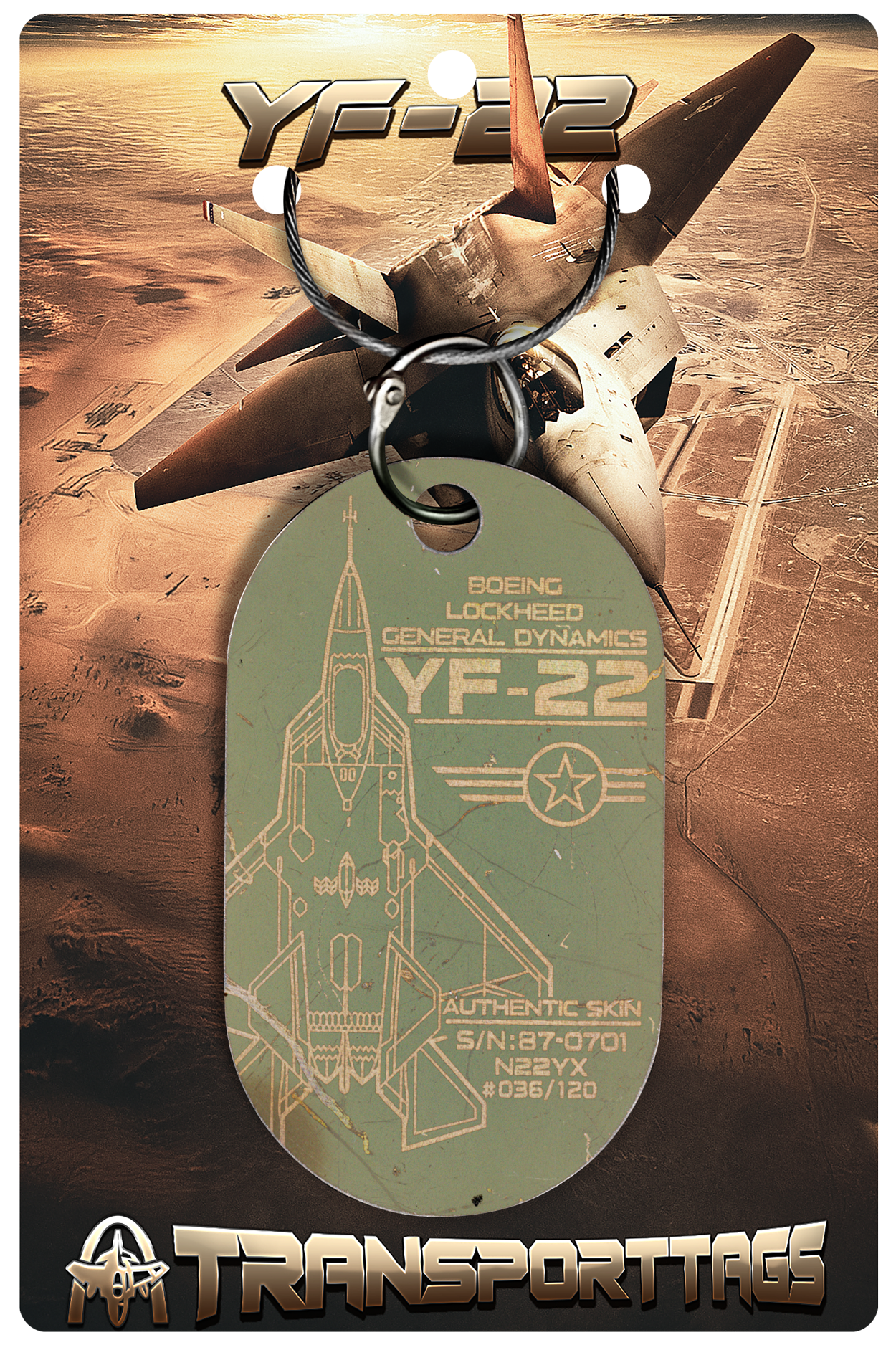

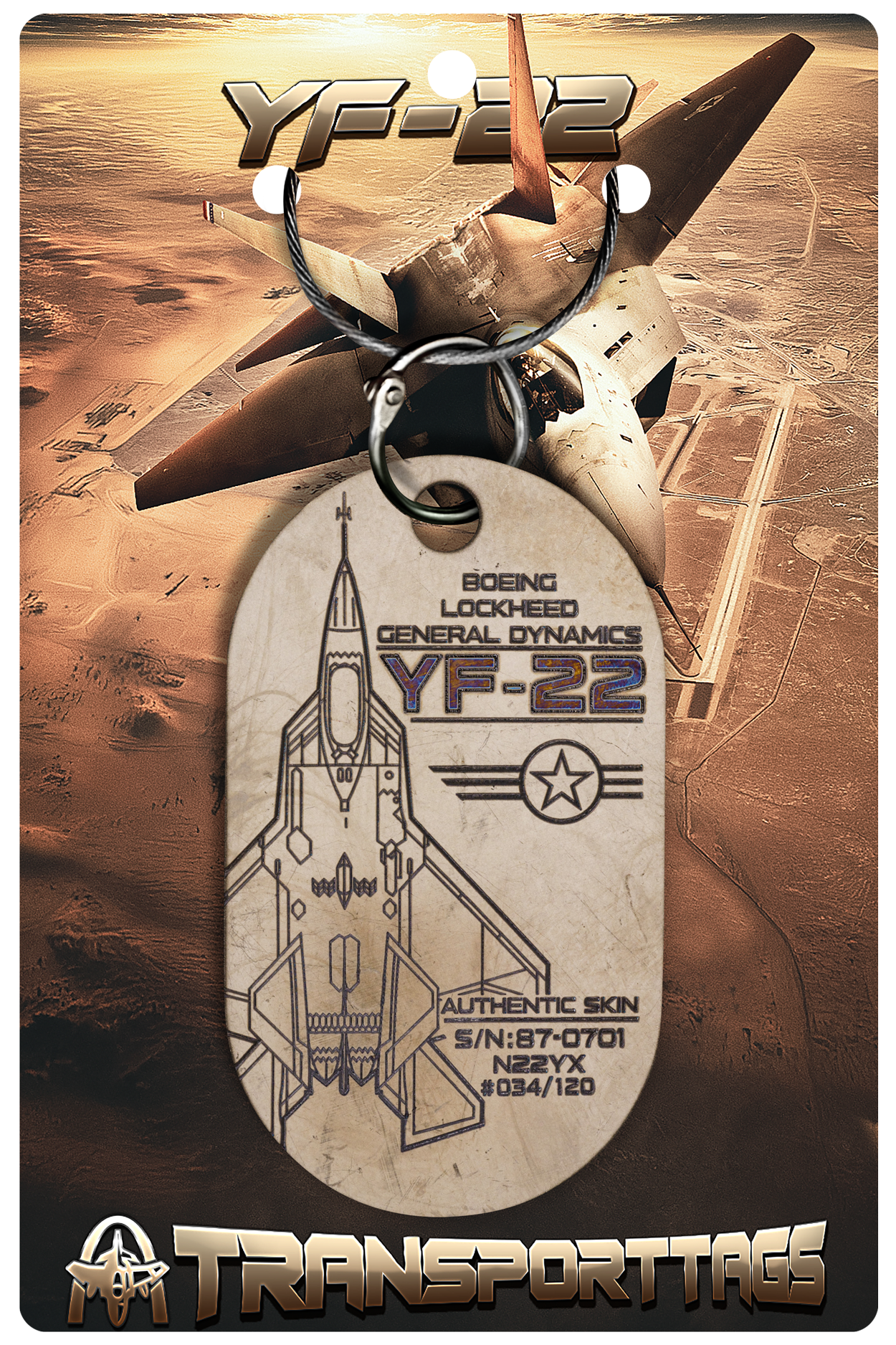

The YF-22, serial number 87-0701 and registered as N22YX, was the second of two prototype aircraft built by Lockheed, Boeing, and General Dynamics for the United States Air Force’s Advanced Tactical Fighter (ATF) program. Designated as YF-22A PAV-2 (Prototype Air Vehicle 2), it first took to the skies on October 30, 1990, piloted by chief test pilot Thomas A. Morgenfeld, following its rollout from Lockheed’s Palmdale facility. Unlike its sibling, PAV-1 (87-0700, N22YF), which was powered by General Electric YF120 engines, PAV-2 was equipped with Pratt & Whitney YF119-PW-100L afterburning turbofans, delivering approximately 23,500 lbf thrust dry and up to 35,000 lbf with afterburner. This aircraft played a critical role in demonstrating the YF-22’s capabilities, including supercruise, high angle-of-attack maneuvers, and internal weapons bay functionality, during the ATF competition against Northrop’s YF-23. Its design, while similar to the production F-22 Raptor, featured distinct differences, such as a more forward-positioned cockpit, larger vertical stabilizers, and a 48-degree wing sweep compared to the F-22’s 42 degrees.

(Please note that Transport Tags LLC is NOT an authorized or licensed distributor of the United States Air Force or of the Boeing, General Dynamics, or Lockheed Aircraft Companies, and uses their names, markings, etc., for identification purposes ONLY in accordance with the Lanham Act).

During its testing phase at Edwards Air Force Base, PAV-2 contributed significantly to the Lockheed team’s victory in the ATF competition, announced on April 23, 1991. The YF-22’s thrust-vectoring nozzles gave it superior maneuverability over the stealthier but less agile YF-23, and PAV-2’s flight tests showcased its ability to meet or exceed performance requirements, including Mach 2-class speeds and enhanced agility. The aircraft was initially nicknamed “Lightning II,” a nod to Lockheed’s P-38 Lightning, though the production F-22 was later named “Raptor.” After completing its flight test program, PAV-2 was retired and is now stored at Rome Laboratory in Rome, New York, where it remains a preserved piece of aviation history. Its testing data helped refine the production F-22A, which evolved through the Engineering and Manufacturing Development (EMD) phase with significant aerodynamic and stealth enhancements, such as a redesigned radome and repositioned engine inlets.

The YF-22 PAV-2, N22YX, represents a pivotal step in the development of modern stealth air superiority fighters. Its contributions extended beyond the ATF program, influencing the F-22 Raptor’s final design, which became the world’s first operational fifth-generation fighter when it entered service in 2005. While PAV-2 itself never saw combat, its role in validating advanced technologies—like stealth, integrated avionics, and thrust vectoring—laid the groundwork for the F-22’s dominance in air-to-air and multirole missions. The aircraft’s legacy is also tied to the broader evolution of Lockheed’s Skunk Works, which pushed boundaries in stealth and performance from the SR-71 to the F-117 and beyond. Stored out of public view, N22YX remains a testament to the engineering ambition of the 1980s and 1990s, when the U.S. sought to counter emerging Soviet threats like the Su-27 and MiG-29 with a fighter that redefined air combat.

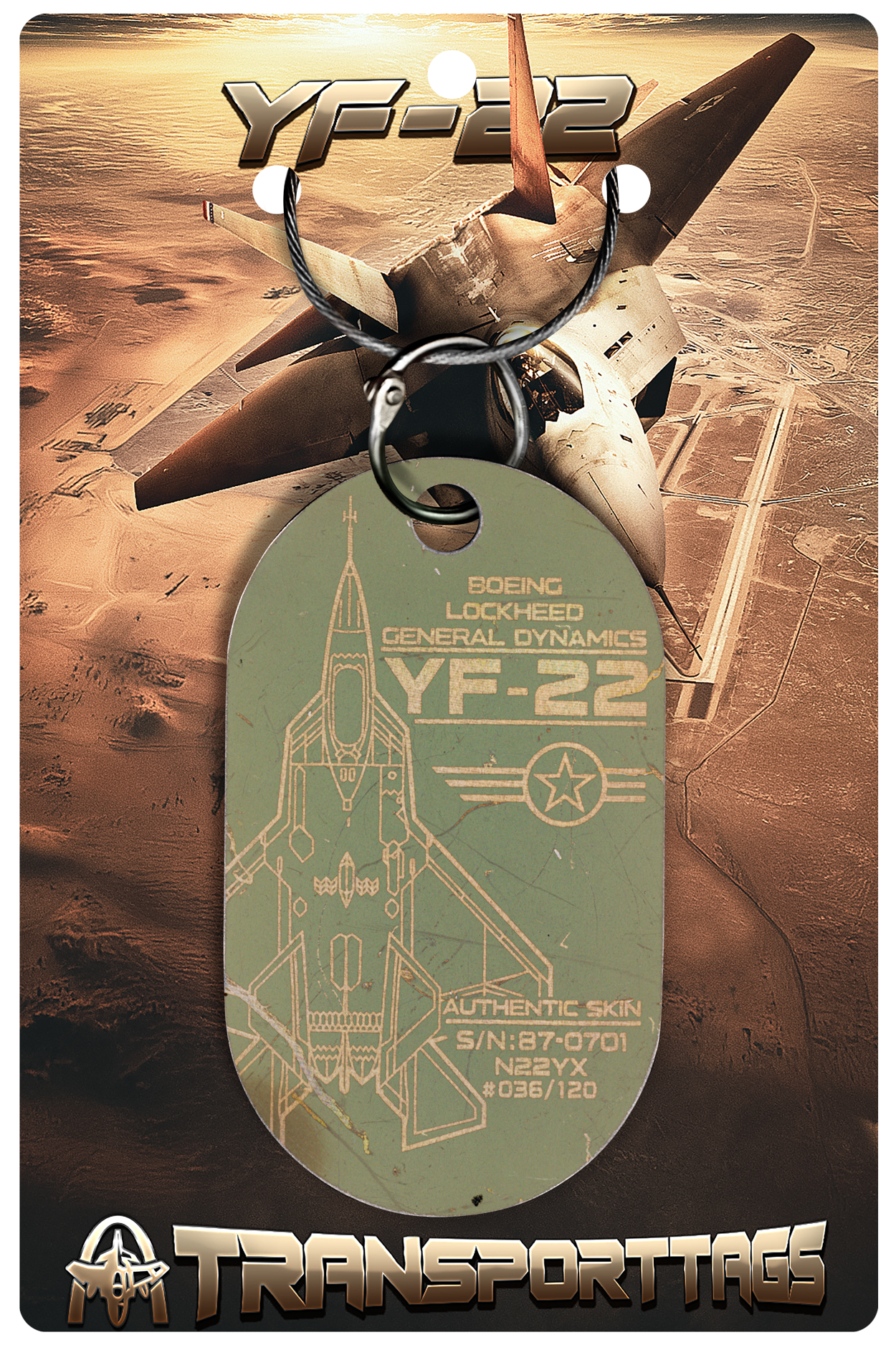

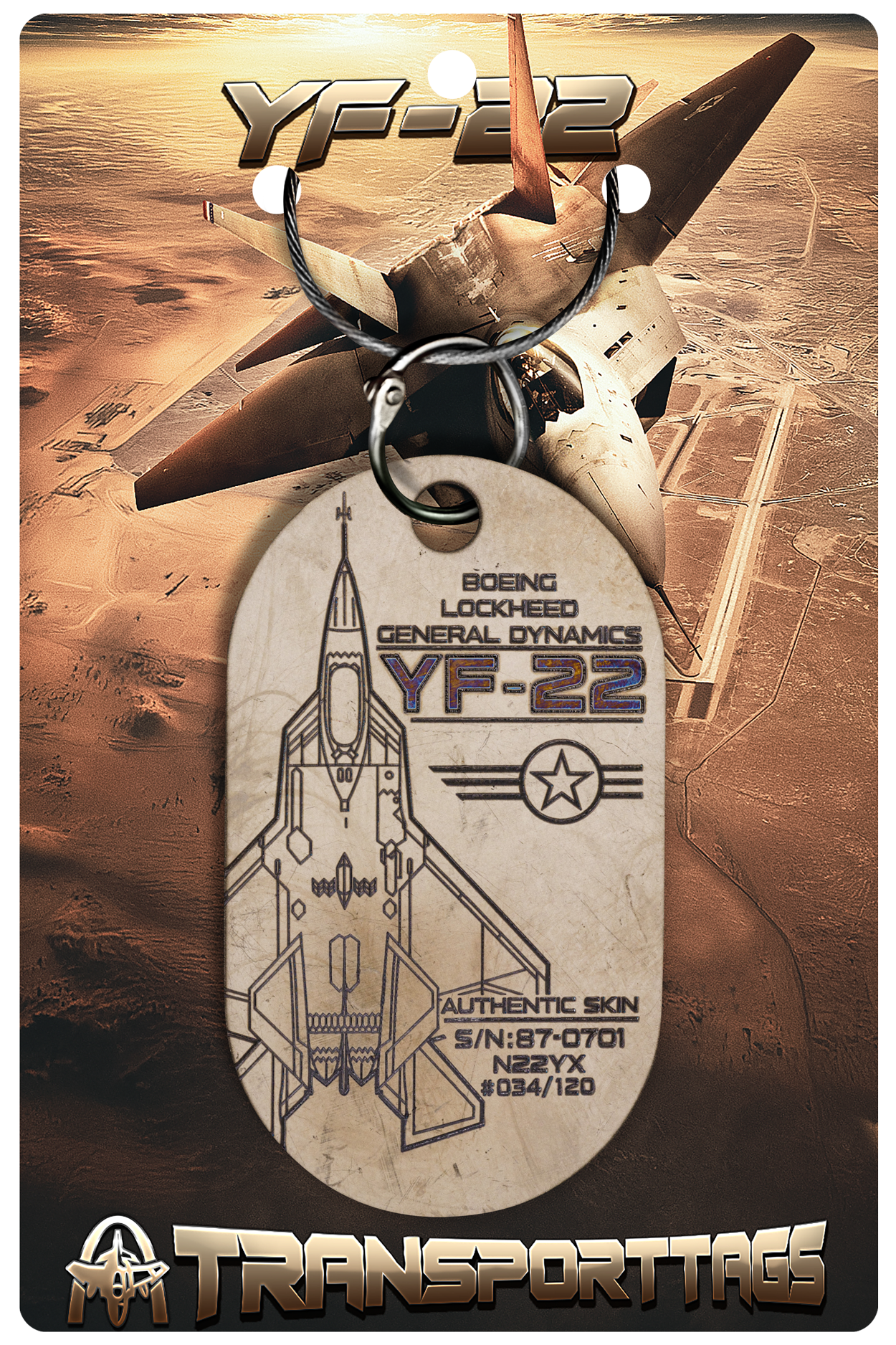

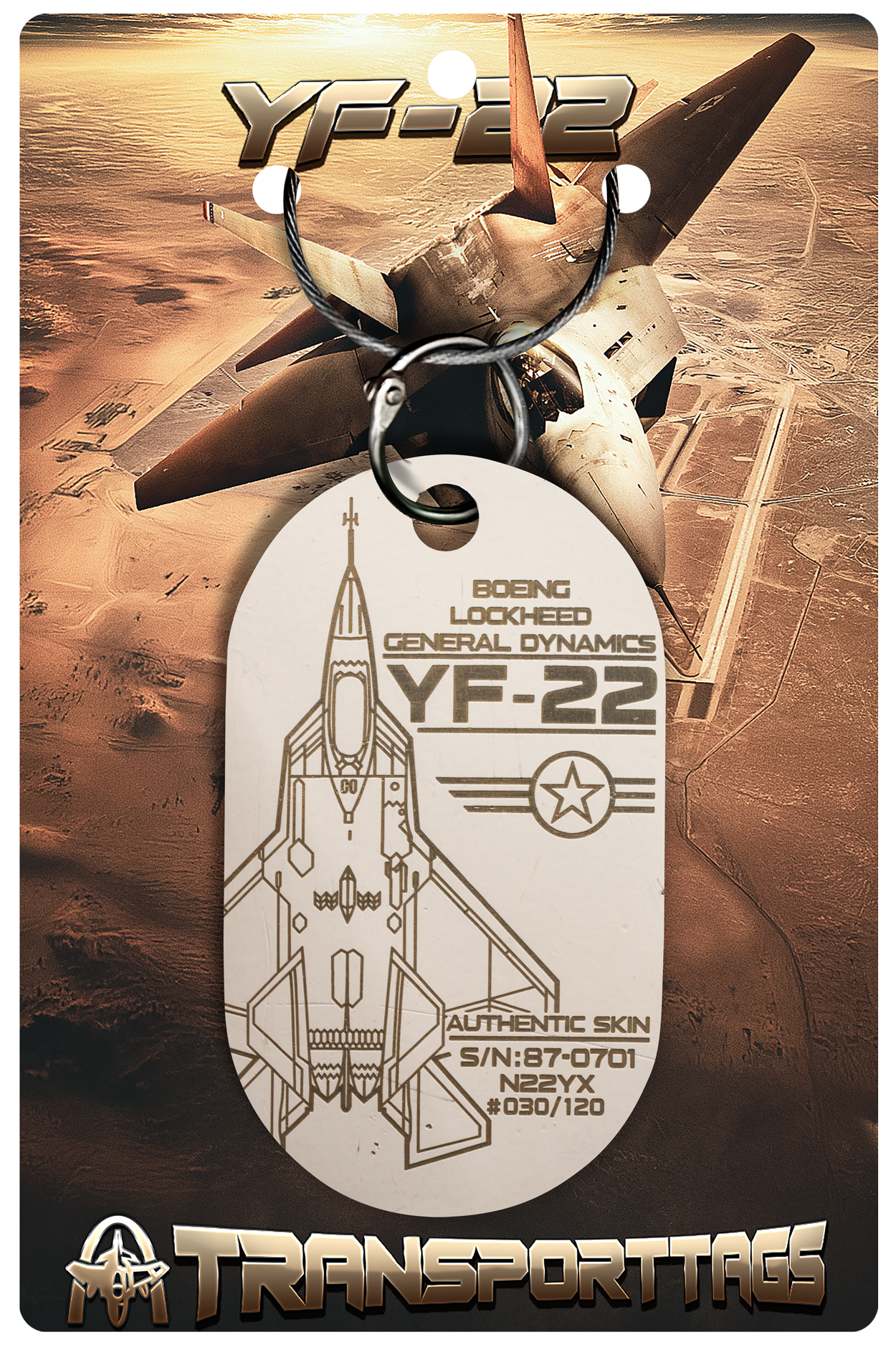

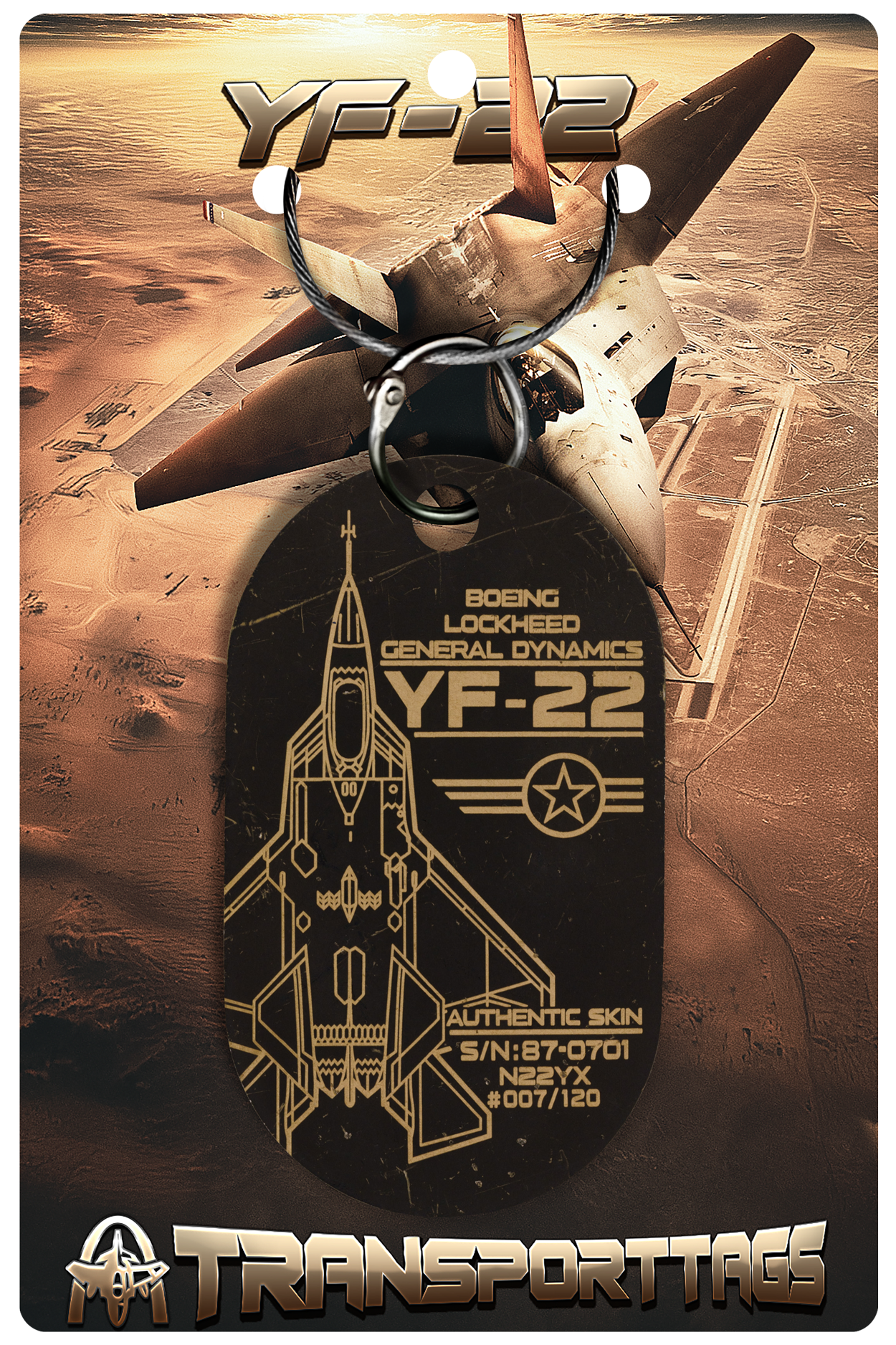

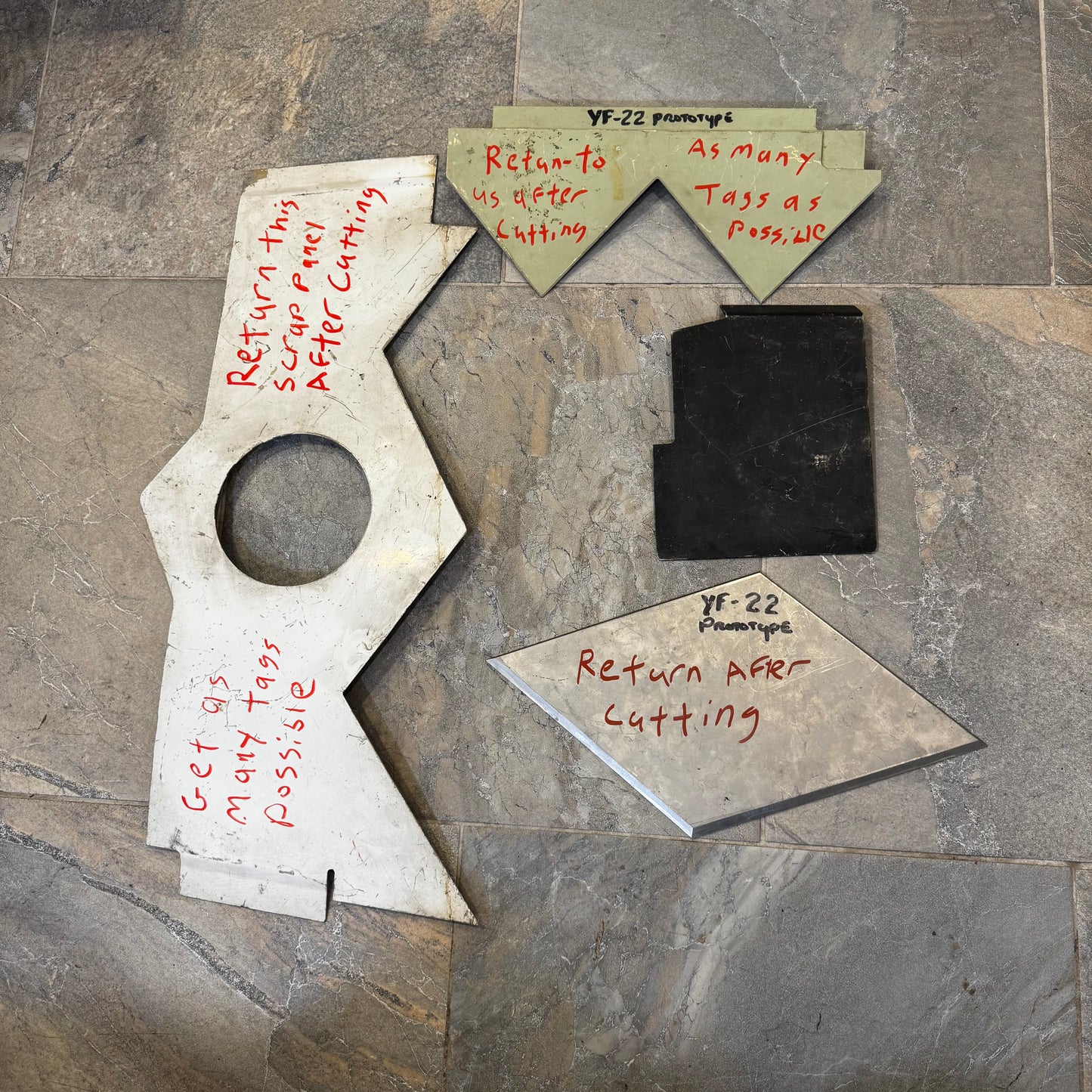

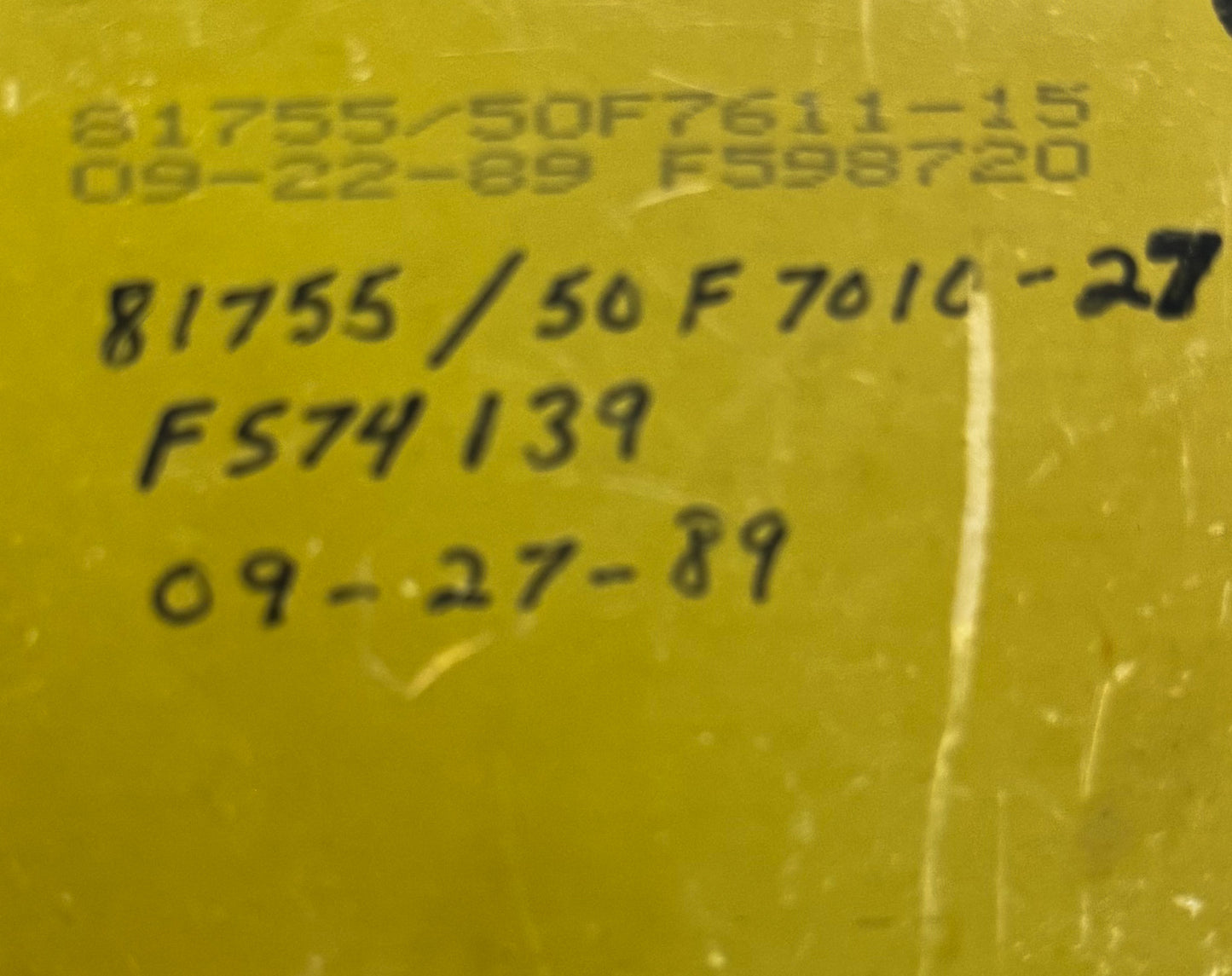

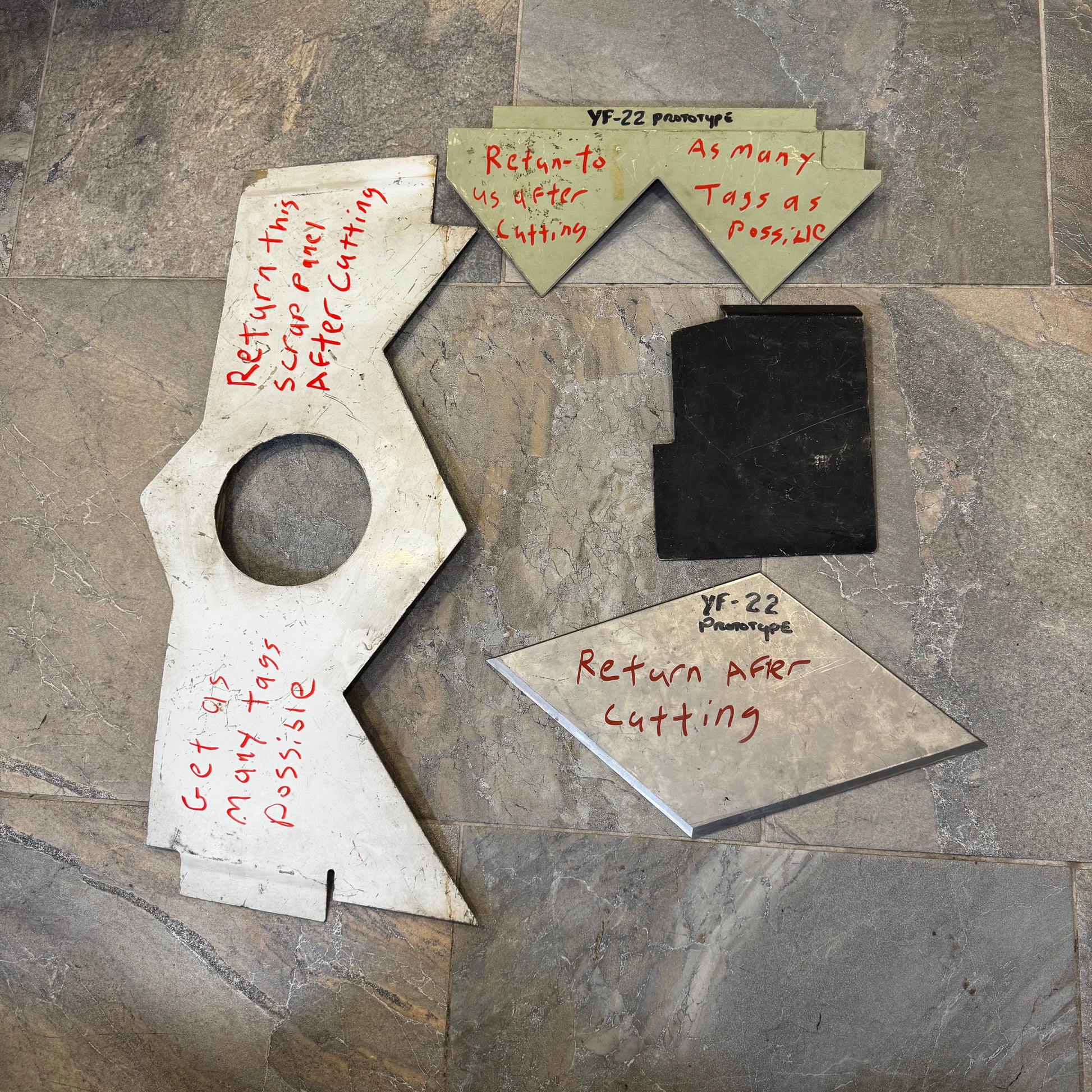

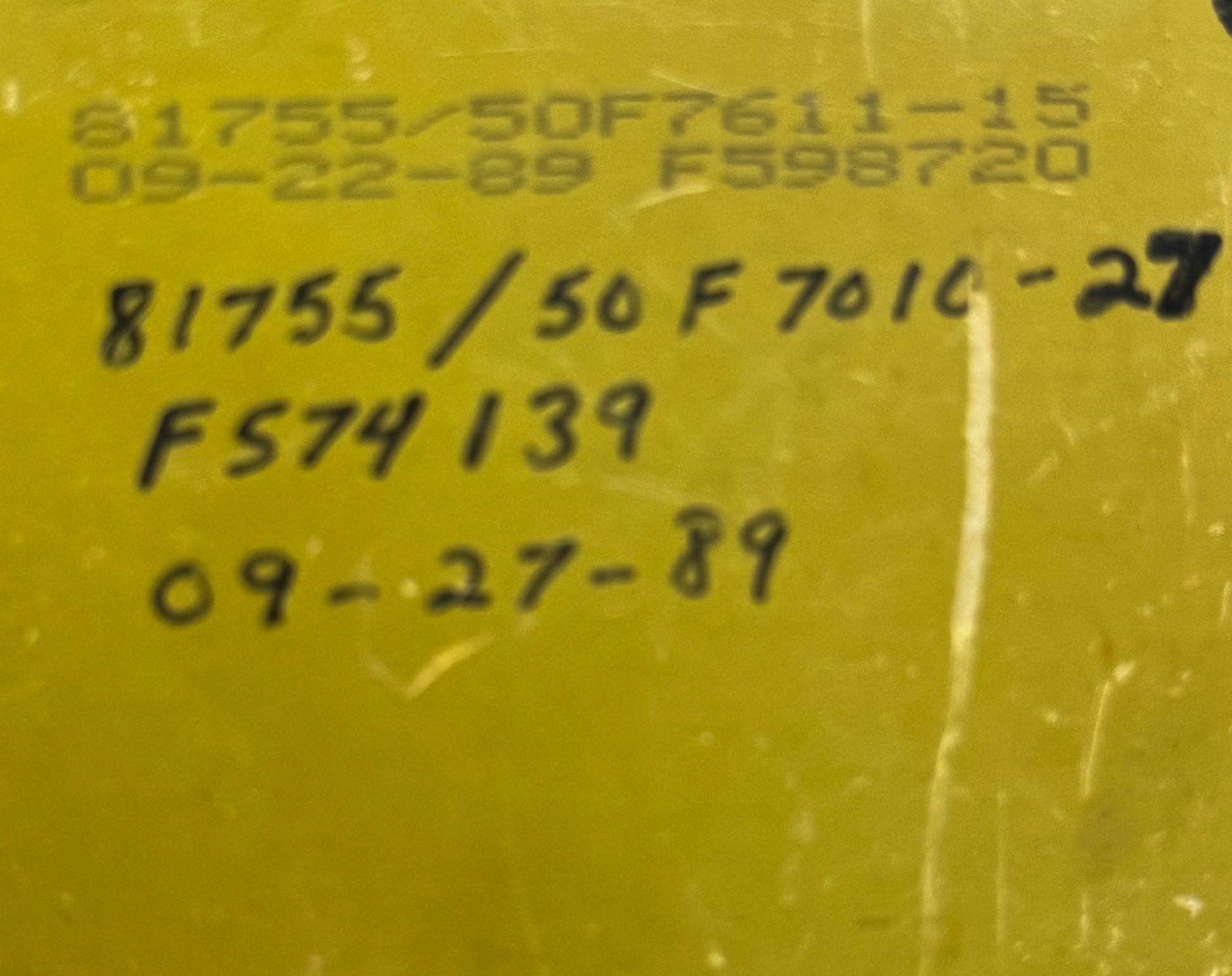

A test flight piloted by Tom Morgenfeld occurred on April 29, 1992, during which N22YX was involved in a crash landing. Subsequently, the aircraft was repaired to static condition, with some declassified panels ending up in civilian hands. TransportTags acquired the panels, which were replaced on N22YX, from a Senior Aviation Archaeologist who spent more than 30 years searching for and finding nearly 1,000 confirmed crash sites, primarily in the Southwestern United States. He served as both an Aviation Editor for an international military magazine and as an Aviation Curator for a Veterans Museum while also authoring several books related to tragic aviation crashes. We are honored to have made his acquaintance and consider him a treasured friend.

TransportTags LLC Statement Regarding “Top-Secret” Materials:

It is important to note that the materials in question are older generation technology, small pieces, and have been scrubbed and demilitarized - adhering to all applicable regulations, thus are no longer considered to fall under any actual top-secret classifications.

We have ensured that these components meet the guidelines which permit the sale and use of such materials under specific conditions. We are also restricting the sale of these tags to United States shipping addresses ONLY. While we would not necessarily be prohibited from selling these tags outside of the United States, we are voluntarily choosing to err on the side of caution - and apologize to collectors who may be disappointed in our decision to do so.

We have diligently ensured the provenance and have legally acquired every complete aircraft, aircraft part, engine, etc., in our collection and will continue to do so.

Moreover, we are not alone in this practice; many other components and panels of the same type/origin/aircraft have been legally sold for quite some time, demonstrating a precedent within the industry. Other aircraft tag companies have also offered tags made from “top-secret” materials as part of their product line. This activity places these materials in the public domain, further validating our right to utilize similar pieces. The legality of these transactions highlights the accessibility of such materials and reinforces our position.

Under U.S. law, specifically the National Defense Authorization Act (NDAA), it is permissible to utilize demilitarized and properly scrapped military materials, provided they meet certain criteria. The Department of Defense (DoD) has established guidelines that allow for the sale and use of materials that have been rendered non-sensitive and non-functional. Our key tags incorporate small pieces that have any classified materials and/or coatings removed/scrubbed ensuring compliance with these regulations.

By way of example, one can draw a parallel to museums where F-117s have been stripped of all sensitive parts, with the bare metal frames being delivered for the museums to build back up - and the volunteers who work on those restorations do not have/require any special clearances.

Additionally, the Defense Logistics Agency (DLA) provides oversight on the disposal and repurposing of military materials, supporting initiatives that promote innovation and sustainability. By using these small components, we are not only adhering to legal standards but also contributing to the repurposing of materials that would otherwise go to waste. They serve as pieces of collectible aviation and aerospace history which promotes goodwill and interest towards those same industries.

Our commitment to transparency, ethical practices and legal compliance is paramount, and we take pride in our efforts to operate within the framework established by the United States military - we take these responsibilities very seriously.

By purchasing and receiving this TransportTag made from “Top-Secret” military aircraft parts ("Product"), the Buyer agrees to the following terms:

1. The Buyer acknowledges that the Product may have contained components or materials that were subject to U.S. military regulations and laws. The Buyer agrees not to misuse, alter, or repurpose any component, material, or coating of the Product in any manner that violates U.S. military law.

2. The Buyer shall not use the Product for any illegal activities or purposes, including but not limited to, unauthorized military applications, weaponization, or any use that could compromise national security.

3. The Buyer agrees to indemnify and hold harmless the Seller from any claims, damages, or liabilities arising from the Buyer's misuse of the Product or violation of this agreement.

4. This agreement shall be governed by the laws of the United States and any applicable military regulations.

By completing the purchase of the Product, the Buyer confirms that they have read, understood, and agreed to the terms of this End Use Agreement.

Vehicle History

Vehicle History

The YF-22 Raptor, serial number 87-0701 (N22YX), emerged from the United States Air Force’s Advanced Tactical Fighter (ATF) program, initiated in the early 1980s to counter advanced Soviet fighters like the Su-27 and MiG-29. The ATF aimed to produce a next-generation air superiority fighter combining stealth, supercruise ability, and advanced avionics. In 1986, the Air Force selected Lockheed (teamed with Boeing and General Dynamics) and Northrop (with McDonnell Douglas) to develop competing prototypes: the YF-22 and YF-23, respectively. Lockheed’s Skunk Works, renowned for the SR-71 and F-117, led the YF-22’s design at its Palmdale, California facility. The YF-22 program was a high-stakes effort, with the winner securing a contract to replace the F-15 Eagle. Development faced intense pressure to balance stealth with aerodynamic performance, requiring innovations like thrust-vectoring engines and radar-absorbent materials. By 1990, two YF-22 prototypes were built, with 87-0701 (PAV-2) powered by Pratt & Whitney YF119 engines, making its first flight on October 30, 1990, piloted by Thomas Morgenfeld.

The YF-22’s development was marked by rapid prototyping and rigorous testing at Edwards Air Force Base, where PAV-2 demonstrated supercruise (sustained supersonic flight without afterburners), high angle-of-attack maneuvers, and internal weapons bay functionality. Unlike the sleeker, stealthier YF-23, the YF-22 emphasized maneuverability, thanks to its 2D thrust-vectoring nozzles, which allowed precise control during dogfights. Lockheed’s team refined the airframe through computational fluid dynamics and wind tunnel testing, though the YF-22’s design differed from the production F-22 with features like a more forward cockpit and larger vertical stabilizers. The ATF competition culminated in April 1991, when the Air Force selected the YF-22 over the YF-23 for its superior agility and growth potential. This victory led to the Engineering and Manufacturing Development (EMD) phase, where Lockheed, Boeing, and Pratt & Whitney (now part of RTX Corporation) evolved the YF-22 into the F-22 Raptor, incorporating a redesigned radome, adjusted wing sweep, and enhanced avionics. PAV-2’s test data was critical in shaping these refinements, though the prototype itself was retired and stored at Rome Laboratory, New York, after the competition.

Lockheed Martin, formed after Lockheed’s 1995 merger with Martin Marietta, became the primary contractor for the F-22 Raptor, with Boeing handling wing and aft fuselage production and Pratt & Whitney supplying the F119-PW-100 engines. The F-22 program faced challenges, including cost overruns and debates over its relevance post-Cold War, but it delivered the world’s first operational fifth-generation fighter in 2005. The YF-22’s legacy, embodied by 87-0701, lies in its role as a proof-of-concept for technologies that defined modern air combat: stealth, sensor fusion, and unmatched maneuverability. Lockheed Martin’s Skunk Works solidified its reputation for pushing aerospace boundaries, building on the YF-22’s success to influence later projects like the F-35. For aviation enthusiasts and historians, N22YX represents a pivotal moment when engineering ambition met strategic necessity, giving rise to a fighter that remains unmatched in air superiority.

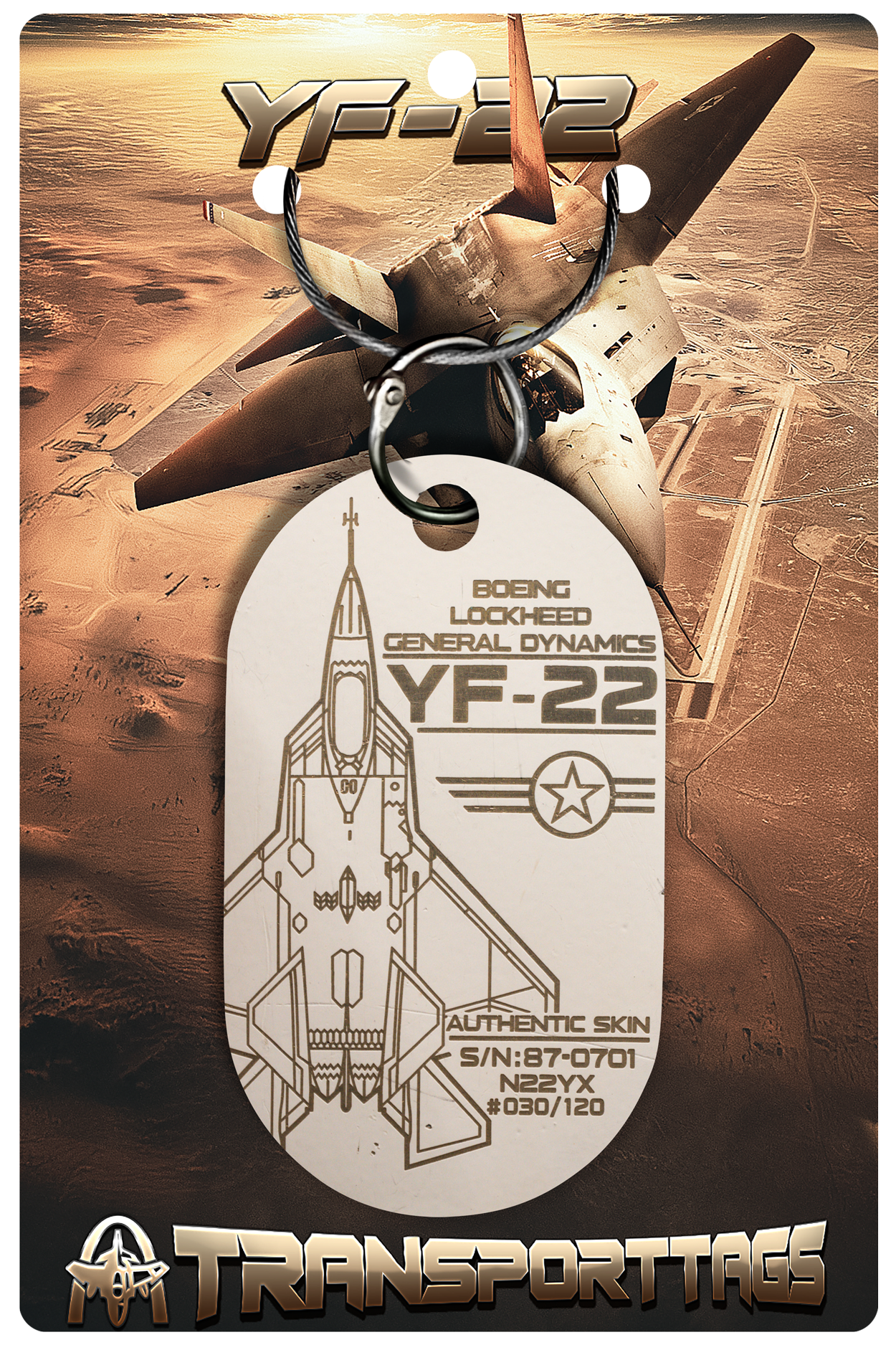

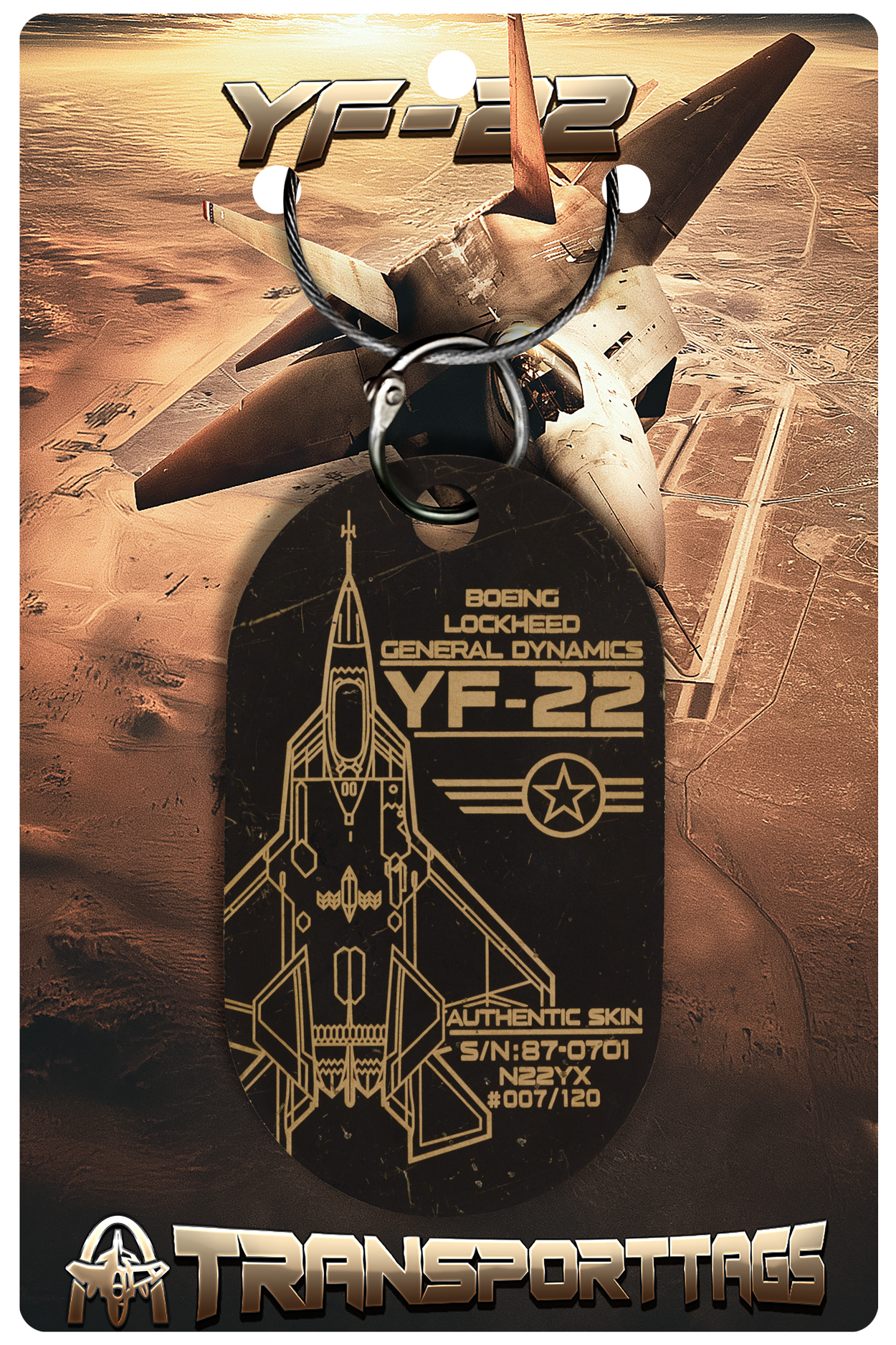

Product Specifics

Product Specifics

Multiple variants available. Tag back will be blank unless customization is requested at checkout.

Vehicle Stats

Vehicle Stats

Top Speed: 1452 mph, Mach 2.2 (2.337 km/h)

Wingspan: 43 FT 0 IN (13.1 M)

Length: 64 FT 2 IN (19.55M)

Engine: 2X General Electric YF120-GE-100L after burning turbo fans

Ceiling: 65,000 FT (19,800 M)

Armament: 1 X 20 MM M61 Vulcan rotary canon, 4XAIM-120 AMRAAM air to air missiles, 2XAIM-9 sidewinder missiles

Product Dimensions

Product Dimensions

Card Dimensions

Length: 5 1/2"

Width: 3 1/2"

Tag Dimensions

Length: 3"

Width: 1.75"

Thickness:

Regular Tags: 1.3mm - 6.8mm

Thick Tags: 9.1mm - 10.5mm

Disclaimer

Disclaimer

TransportTags are unique, handcrafted pieces made from genuine vehicle skin. Features like scratches, blemishes, or minor discolorations testify to their unique vintage appeal and authenticity. By purchasing, you accept the product may differ slightly from website images. Transport Tags LLC uses authentic material from transportation vehicles, potential containing hazardous substances. Not intended for ingestion, inhalation, or use by small children. Transport Tags LLC is an independent company, not affiliated with, sponsored or endorsed by any entities. We use branded names and insignia for identification under the provisions of the Lanham Act, without implying any association or endorsement. For more information, read our detailed product safety and legal information here.

Share